Release time:2023-11-14 08:41:08 Hits: Current position: Home > News

This article mainly introduces:

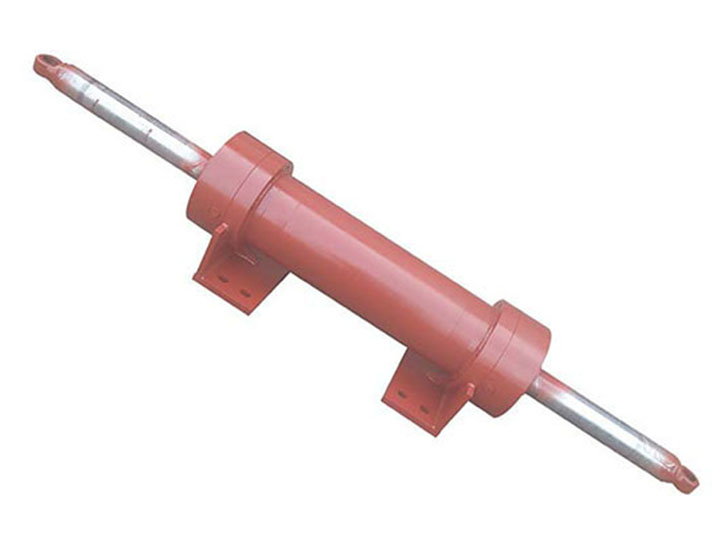

Estonia hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Estonia track steering cylinder,produced by Hengyu Group)

track steering cylinder are widely used in Estonia,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed track steering cylinder for customers from Estonia.

The track steering cylinder pipe should not be left behind when deburring at both ends after the fixed length processing. In addition, the placement of steel pipes near the site of welding pipeline operations is the cause of welding foreign objects. The pipes placed near the welding operation site should be sealed. It must also be noted that pipe fitting materials should be fully prepared on a dust-free workbench.

The viscosity of the working oil used in the track steering cylinder is 29~74mm2/S, and ISO VG46 anti-wear hydraulic oil is recommended. Working oil temperature within the range of -20~80. C. When the ambient temperature and service temperature are low, the oil with lower viscosity can be selected.

If the track steering cylinder piston rod is found to be worn, it can be brushed and plated first, then ground, and finally adjust the mating accuracy of the piston rod and the guide sleeve. At this time, the guide sleeve can be properly redrilled or the guide sleeve can be re-turned. When making the above repairs, remember to replace various rubber seals in time.

The assembly work of the track steering cylinder has a great impact on the quality of the track steering cylinder: each part must be carefully cleaned before assembly; To correctly install the sealing device everywhere: when installing the sealing ring, pay attention to its installation direction to avoid oil leakage due to installation, and its lip should be equipped with a pressure oil chamber. In addition, because it is a YX-shaped sealing ring, it is necessary to pay attention to distinguish between shaft and hole use, do not install wrong; Because the sealing device is matched with the sliding surface, an appropriate amount of hydraulic oil should be applied during assembly; The special wrench should be used when the threaded coupling is tightened, and the torque should meet the standard requirements; After the piston and piston rod are assembled, it is necessary to measure whether the coaxiality and straightness on the full length are out of whack. After assembly, there should be no blocking sensation and uneven resistance when the piston assembly moves.

How to judge the failure of forklift hydraulic cylinder?

The common faults of the hydraulic cylinder of forklift truck are mainly crawling, insufficient thrust, working speed decline or even stop. Generally, crawling occurs at low speed. The main reason is that the air stored in the cylinder is not cleared. In addition, excessive or uneven mechanical friction can also cause crawling. Such as the piston and the piston rod different heart, the piston rod full length or local bending, the cylinder hole straightness is poor, the cylinder is drum shaped or has a large taper, the cylinder thin finish decline or produce hair, the cylinder installation accuracy is out of whack, the piston rod nuts at both ends of the screw too tight to make its concentricity is poor, the oil seal screw too tight friction is too large, will cause crawling.

Is it good or bad for the hydraulic cylinder working in the limit stroke position?

It is not good for the hydraulic cylinder working in the limit stroke position. Generally, when the cylinder is used in the limit stroke, the oil in the cylinder will form a backflow back pressure impact on the piston and guide sleeve seals. If the limit is not accurate, it is easy to cause collision damage. It is recommended to leave a buffer of ten to twenty centimeters.