Release time:2023-11-09 08:46:17 Hits: Current position: Home > News

This article mainly introduces:

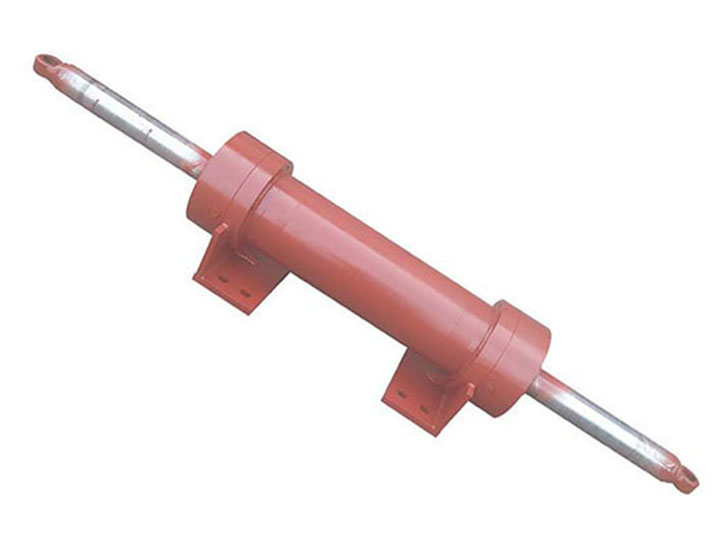

Guatemala hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

(Guatemala vehicle hydraulic cylinder,produced by Hengyu Hydraulic Co., Ltd)

vehicle hydraulic cylinder are widely used in Guatemala,because of no need for deceleration device,long service life,smooth movement.So our company has designed vehicle hydraulic cylinder for customers from Guatemala.

The cavitation of the vehicle hydraulic cylinder has a great influence, and to avoid it, it is necessary to use the hydraulic oil reasonably and ensure the quality of the hydraulic oil. If the anti-foam property of the oil is poor, it is easy to produce foam, resulting in cavitation. Secondly, the change frequency of oil pressure is too fast and too high, which will also directly cause the formation of bubbles and accelerate the rupture rate of bubbles. The test shows that the speed of cavitation will be accelerated in the part with high frequency of pressure change. For example, at the inlet and outlet of the vehicle hydraulic cylinder, due to the relatively high frequency of pressure changes, the degree of cavitation is also relatively higher than that of other parts. In addition, overheating of the oil will also increase the probability of cavitation.

vehicle hydraulic cylinder is the most important part of construction machinery, the traditional processing method is: broaching vehicle hydraulic cylinder block - fine boring vehicle hydraulic cylinder block - grinding vehicle hydraulic cylinder block. The rolling method is: broaching vehicle hydraulic cylinder block - fine boring vehicle hydraulic cylinder block - rolling vehicle hydraulic cylinder block, the process is 3 parts, but the time is compared: grinding 1 meter of the vehicle hydraulic cylinder block is about 1-2 days, rolling 1 meter of the vehicle hydraulic cylinder block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3 μm before rolling to Ra0.4 ~ 0.8μm, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the vehicle hydraulic cylinder increases by 25%. If the vehicle hydraulic cylinder life is only considered, it is increased by 2 to 3 times, and the boring and rolling process is 3 times more efficient than the grinding process In particular, if you want to make high-quality vehicle hydraulic cylinders, you must take the rolling production process. After the vehicle hydraulic cylinder is rolled, there is no sharp tiny edge on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.

When the vehicle hydraulic cylinder needs to be disassembled for maintenance due to leakage and other faults, the piston should be moved to the bottom position of the vehicle hydraulic cylinder, and hard beating and sudden drop are strictly prohibited during disassembly.

The oil vehicle hydraulic cylinder is a part of the hydraulic system, in the hydraulic system, to reasonably design the heat dissipation system, to prevent the oil temperature is too high is the key to keep the hydraulic oil temperature normal. The temperature of the system should be kept in a suitable range to reduce the energy released when the bubble bursts. While not affecting the normal circulation of the coolant, a certain amount of anti-corrosion additives can be appropriately added to inhibit rust. When operating the hydraulic system, we should strive to be stable, not too fast, too strong, and try to reduce the impact of hydraulic oil on hydraulic components.

What is the main maintenance of the cylinder?

After disassembling the cylinder: 1, clean the cylinder and piston; 2, replace all seals; 3, if there is a valve to repair, to ensure sealing and flexible; 4, deal with all deformation parts; 5. Installation experiment.

What is the difference between hydraulic cylinder self-adjusting buffer and adjustable buffer?

If it is the buffer device inside the cylinder, then there are 4 basic forms, cylindrical buffer device, conical buffer device, variable throttle and adjustable flow groove. The biggest difference between the first three and the latter is that the latter can be adjusted through the external thimble to change the buffer strength, the first three mainly rely on the buffer device and buffer groove form to achieve the buffer (among them, the first type of buffer strength will not change, and the buffer strength of the two and three forms of buffer devices can be gradually increased).