Release time:2023-11-12 11:06:15 Hits: Current position: Home > News

This article mainly introduces:

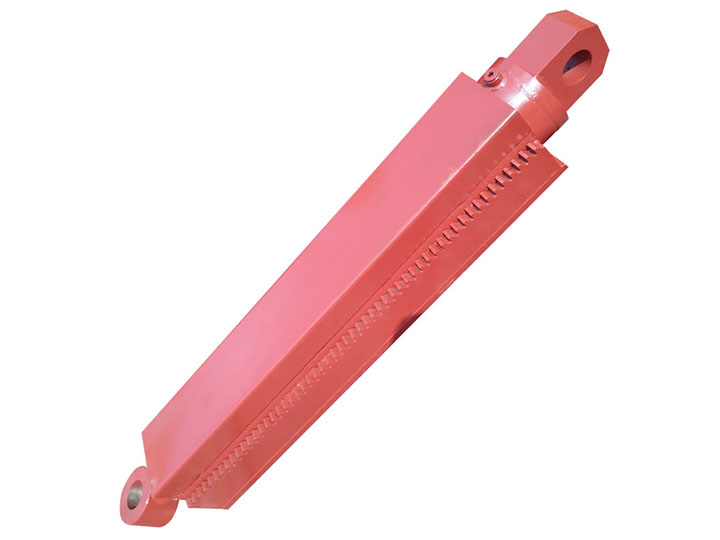

Libya hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Libya single rack cylinder,produced by Hebei Hengyu company)

single rack cylinder are widely used in Libya,because of simple structure and reliable operation,excellent temperature resistance,no transmission clearance.So our company has designed single rack cylinder for customers from Libya.

If the seal of the single rack cylinder is abnormal wear, you can check whether the speed control valve is improperly adjusted, resulting in too high back pressure and improper installation of the seal or hydraulic oil contamination. The second is whether there is a foreign body entering the assembly and the quality of the sealing material is not good. The result is that the action is slow and weak, and in serious cases, it will cause damage to the piston and single rack cylinder, and the phenomenon of "pulling the single rack cylinder" appears. The treatment method is to adjust the speed control valve, and the necessary operation and improvement should be done according to the installation instructions.

The internal leakage of the single rack cylinder should be prevented when the single rack cylinder is used. The internal leakage of single rack cylinder includes the leakage caused by excessive wear of single rack cylinder block seal, piston rod and seal cover seal and piston seal. The cause of sealing leakage between the piston rod and the seal cover is that the seal is wrinkled, squeezed, torn, worn, aging, deterioration, deformation, etc., and a new seal should be replaced at this time.

When the long-stroke single rack cylinder rotates horizontally, the piston rod bends due to its own weight, causing the guide sleeve and piston to produce biased load, resulting in single rack cylinder head seal damage, oil leakage, and piston sleep in the single rack cylinder. The following measures can be taken: increase the piston plan to adjust the piston outer circle and process it into a convex drum, so that the piston can self-position, improve the force situation, and reduce and avoid pulling the single rack cylinder; The piston and the piston rod are connected with a spherical joint.

The oil single rack cylinder is a part of the hydraulic system, in the hydraulic system, to reasonably design the heat dissipation system, to prevent the oil temperature is too high is the key to keep the hydraulic oil temperature normal. The temperature of the system should be kept in a suitable range to reduce the energy released when the bubble bursts. While not affecting the normal circulation of the coolant, a certain amount of anti-corrosion additives can be appropriately added to inhibit rust. When operating the hydraulic system, we should strive to be stable, not too fast, too strong, and try to reduce the impact of hydraulic oil on hydraulic components.

Why does the hydraulic cylinder not return?

For a spring return cylinder, it is possible that 1, the spring is damaged. You can check it for processing. 2, the oil in the oil path is not unloaded, causing it to be unable to reset. 3, the cylinder piston is dead, resulting in no position. For double-acting cylinders, it is possible to: 1, the spool is not reversed, or is not changed to the correct position, check whether the reversing valve is normal (and whether there is electricity). 2, the cylinder piston is dead, resulting in no position, check and treatment can be. 3, the return oil pressure is insufficient, the inlet oil is not unloaded, the operation is not smooth. For reference only.

Why the lifting cylinder falling by itself?

May be there is a pressure relief point. Check and repair the following parts: whether there is oil leakage in the transparent pipe at the top of the cylinder: the cylinder oil seal is broken, and the cylinder and oil seal need to be replaced; No: The multiway valve has pressure relief and needs to be repaired. Maintenance in accordance with routine maintenance items can reduce mechanical failures: 1. Check whether the thermostat works normally. 2, check the transmission shift work is normal. 3. Check the tightness of the fan belt. 4, check whether the diesel tank oil inlet filter is blocked or damaged, and clean or replace the filter. 5. Check and adjust the valve clearance.