Release time:2023-11-15 10:41:38 Hits:97 Current position: Home > News

This article mainly introduces:

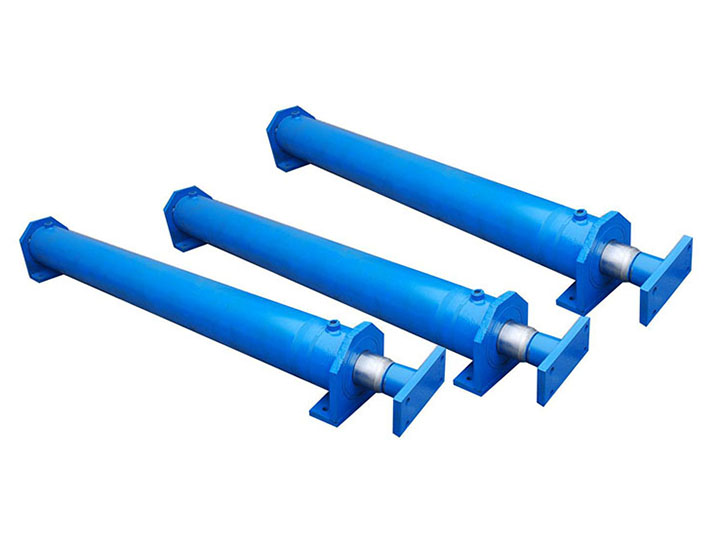

Korea hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Korea push and pull the cylinder,produced by Hengyu Hydraulic Cylinder Factory)

push and pull the cylinder are widely used in Korea,because of powerful torque,excellent temperature resistance,no transmission clearance.So our company has designed push and pull the cylinder for customers from Korea.

If the push and pull the cylinder operation failure, you can start from these aspects to troubleshoot: (1) the hydraulic system control pressure is too low. The throttling resistance in the control line may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is disturbed. At this time, the control pressure source should be checked to ensure that the pressure is adjusted to the specified value of the system; (2) Air enters the hydraulic system. Mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced. (3) The initial action of the push and pull the cylinder is slow. In the case of low temperature, the hydraulic oil viscosity is large, poor flow, resulting in slow push and pull the cylinder action. The improvement method is to replace the hydraulic oil with better viscosity and temperature performance If the push and pull the cylinder is weak and cannot push the load, please check the internal leakage problem. The internal leakage of the push and pull the cylinder includes the leakage caused by excessive wear of the push and pull the cylinder block seal, the piston rod and the seal cover seal and the piston seal. The cause of sealing leakage between the piston rod and the seal cover is that the seal is wrinkled, squeezed, torn, worn, aging, deterioration, deformation, etc., and a new seal should be replaced at this time. The main cause of excessive piston seal wear is improper adjustment of the speed control valve, resulting in excessive back pressure and improper seal installation or hydraulic oil contamination. The second is that foreign bodies enter the assembly and the quality of sealing materials is not good. The result is that the action is slow and weak, and in serious cases, it will cause damage to the piston and push and pull the cylinder, and the phenomenon of "pulling the push and pull the cylinder" appears. The treatment method is to adjust the speed control valve, and the necessary operations should be done according to the installation instructions.

In recent years, the processing process of the push and pull the cylinder generally adopts the rolling method, which is a pressure finishing processing, which uses the cold plastic characteristics of the metal at room temperature, and uses the rolling tool to exert a certain pressure on the surface of the workpiece, so that the surface metal of the workpiece produces plastic flow, and fills in the low concave trough of the original residue, and the roughness value of the workpiece surface is reduced. Due to the plastic deformation of the rolled surface metal, the surface tissue is cold hardened and the grain is fine, forming a dense fiber, and forming a residual stress layer, and the hardness and strength are increased, thus improving the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

The push and pull the cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and does linear reciprocating motion (or swinging motion). It is simple in structure and reliable in operation. When it is used to achieve reciprocating movement, the deceleration device can be eliminated, and there is no transmission gap, and the movement is smooth, so it is widely used in various mechanical hydraulic systems. The output force of the push and pull the cylinder is proportional to the effective area of the piston and the pressure difference between the two sides; The push and pull the cylinder is basically composed of push and pull the cylinder and push and pull the cylinder head, piston and piston rod, sealing device, buffer device and exhaust device. Buffer device and exhaust device depending on the specific application, other devices are essential.

If the seal of the push and pull the cylinder is softened and sticky, it may be that the seal is incompatible with the hydraulic oil or the nearby lubricating oil, replace the appropriate seal; If the seal becomes hard and loses elasticity, most of it is because the ambient temperature is too high (more than 80 ° C), make appropriate temperature insulation protection or replace the high temperature seal.

What material should be selected to seal the cylinder?

The choice of material for sealing is related to the working environment, strength, and medium of your equipment.

What is the safety factor of 25MPa cylinder wall thickness?

Safety factor n can take 3 cylinder material allowable stress [s]=sb/n δ/D=0.08 ~ 0.3 cylinder wall thickness δ=PMAX*D/ (2.3[s]-3PMAX) δ/D≤0.08 cylinder wall thickness δ=PMAX*D/2[s] P < 16MPa, Pmax=1.5Pn; P > 16MPa, Pmax=1.25Pn cold-drawn tube or honing tube is better!